Every day, industry faults are detected and failures prevented through experienced operators sensing that something doesn’t sound, feel or look right. It might be a change in the background noise of a water pump station, the rattle of a loose bearing or a myriad of other things that experienced personnel look out for, but they all tell a story to the listener. This is a story that isn’t told by standard control and measurement systems, but it is just as valuable.

Unfortunately, experience is thin on the ground, expensive, and gaining it can take many years. Equally, operators may only have limited access to critical pieces of infrastructure to assess their condition.

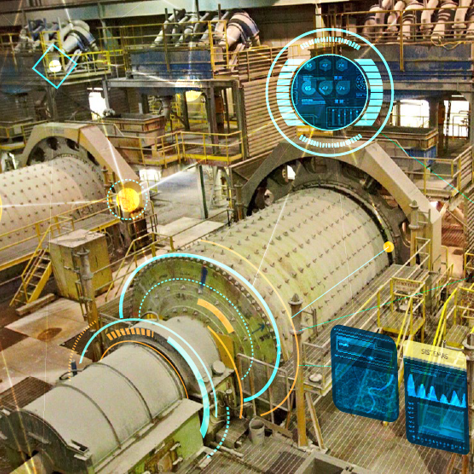

This no longer need be the case. Advances in sensing technology, edge computing and AI are now replicating the ear of the experienced operator. Imagine a network of smart sensors on every piece of critical equipment listening out for and processing changes 24/7, which are monitored remotely and ‘trained’ to alert when key parameters step outside of normal – Stoke SmartEdge devices are doing just this.

Today’s sensors are orders of magnitude more sensitive than the human ear. They can listen for frequencies beyond human hearing and detect minute shifts in vibration that are otherwise not discernable to personnel. This enables much earlier fault detection and true condition based maintenance – ultimately saving money, improving safety and increasing production.

Stoke is at the heart of this revolution and our solution, SmartEdge, brings a new level of precision and simplicity to monitoring critical plant and infrastructure. Contact us to find out more about how we can bring this new version of the Ear of an Experienced Operator to your business.