The concept behind Predictive Maintenance is simple. You gather data from your equipment to identify what causes issues and when they typically occur. Then you use that data to predict when your equipment will fail (or begin causing other issues). By enacting preventative action before failure happens, you can ensure that your assets remain up and running…and ultimately increase asset uptime.

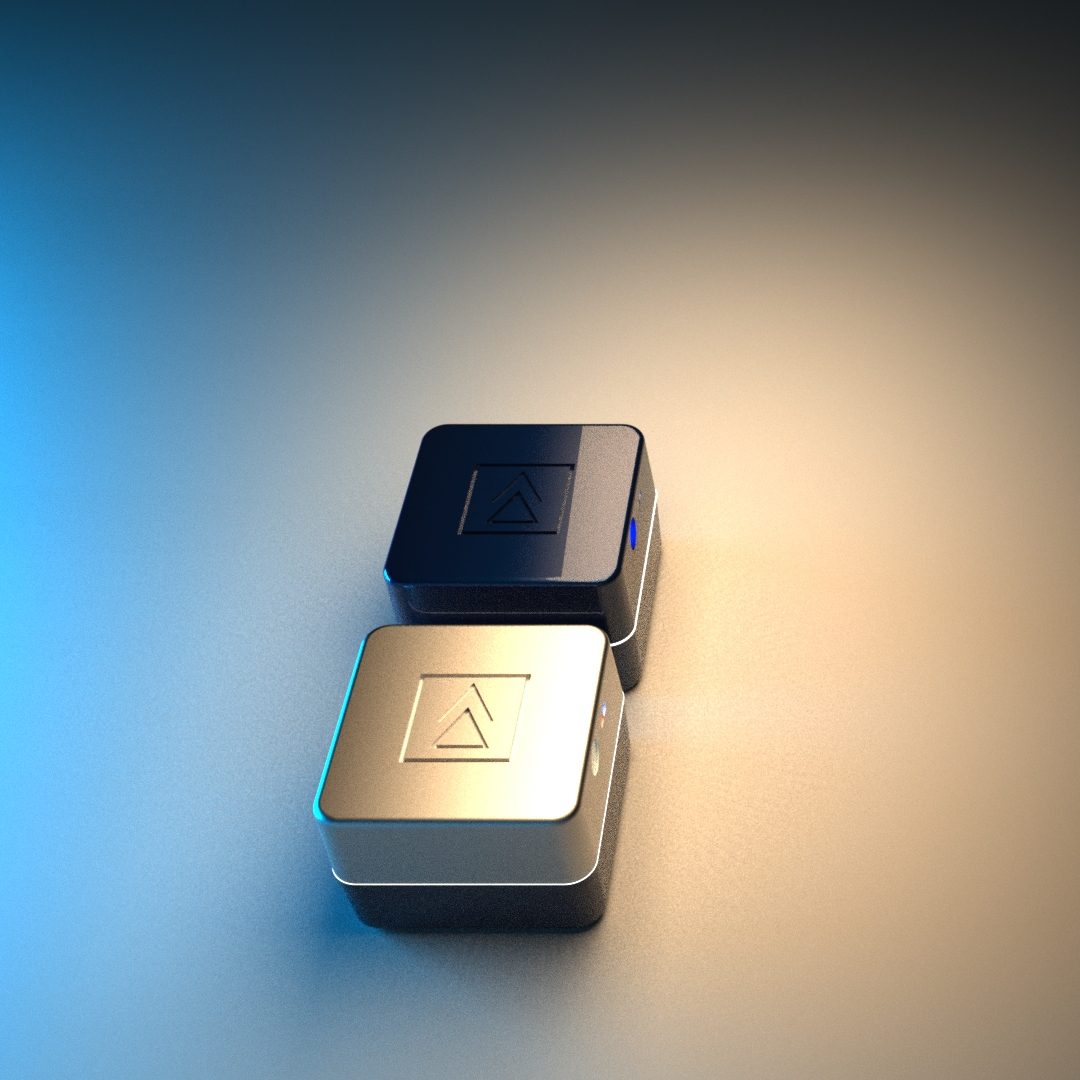

But how do you know when your equipment needs maintenance? It can be hard to tell just by looking at it. But now you don’t have to guess. SmartEdge devices from Stoke attach to equipment and monitor key machine health data in real time, then feed that data into an online dashboard to identify red flags as soon as they appear. The platform can then send technicians automatic, real-time alerts for predictive maintenance—so you don’t have to wait for your machines to break down before fixing them.

Remote asset monitoring is a highly-useful tool that has the potential to increase uptime and reduce operating costs. Click here to schedule a SmartEdge demo to see if our insights can help your organization be much more prepared for asset downtimes when they inevitably occur.